MIG/MAG WELDING MACHINES

EXCEPTIONAL YET AFFORDABLE !

The MIG/MAG welding machines from Soldatech powered by HG are equipped with the latest innovations and extensive configuration options. This makes the devices suitable for every user and every budget. Each MIG/MAG welding machine is designed to allow both MIG/MAG, MMA and gasless wire welding.

All MIG/MAG welders are equipped with an interchangeable torch with euro connector, a sturdy ABS case, a clear digital display and are infinitely adjustable. Different devices are also synergetic, which means that the most ideal settings are easily and automatically generated.

All Soldatech by HG MIG/MAG welding machines are equipped with the following functions:

![]()

ML175E

With this 4 in 1 welding machine, it is possible to weld MIG/MAG, MMA Electrodes, Lift-TIG and gas-free. Ideal for welding steel, stainless steel and aluminium.

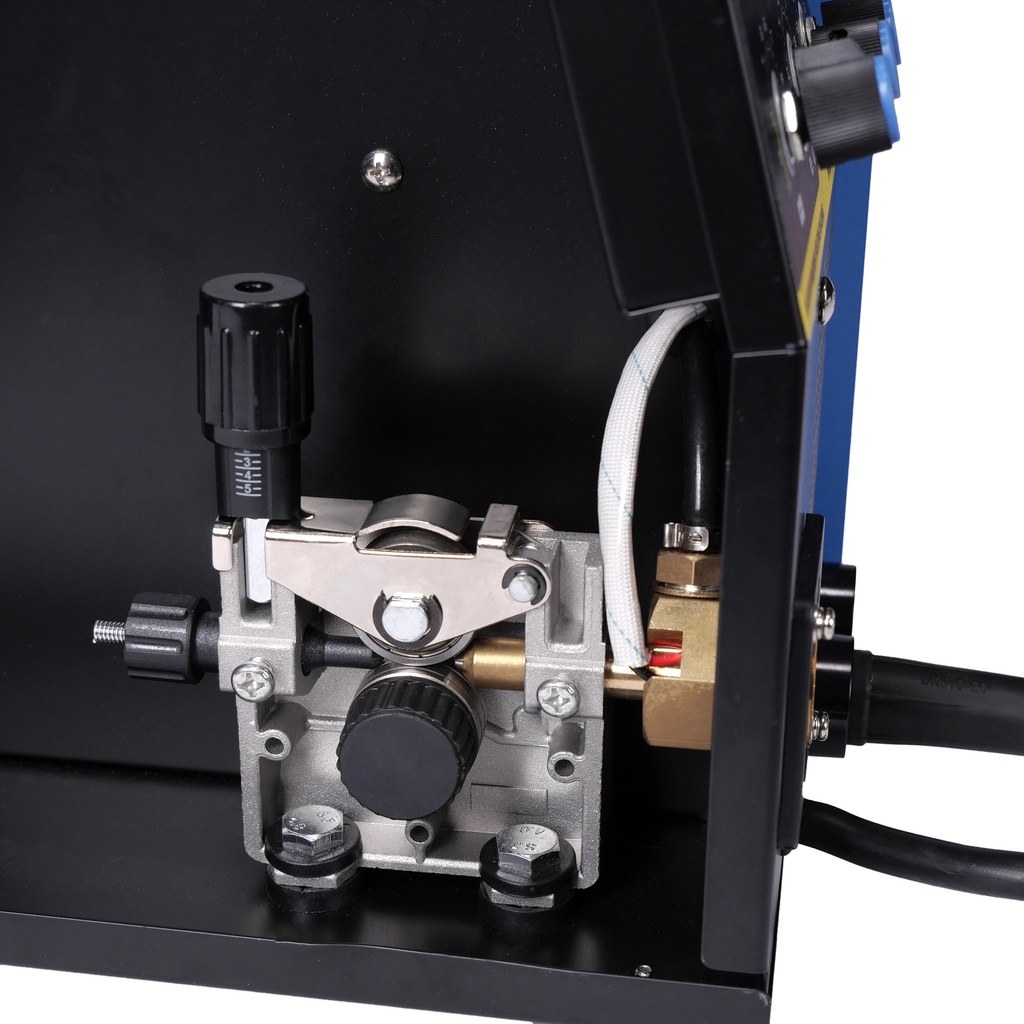

This MIG welding machine is the most comprehensive machine among the Soldatech Originals. It is possible to weld MIG, MMA-Electrodes and lift TIG with it. Even FLUX welding without gas is possible. The ML175E is portable, easy to operate and has the following strong features: IGBT inverter technology: sustainable performance with more power. High-quality aluminum wire feeder. Induction regulator: with this control both the width and the depth of the weld pool can be regulated. Digital display for welding current and voltage. Overload protection in combination with a built-in fan. Infinitely adjustable. Hot-start: high start-up voltage, ignition in any situation. Anti-stick: ensures that electrodes do not stick and are easy to weld. 2-stroke / 4-stroke switching: with 2-stroke switch, hold down to use, ideal for small parts. With 4-stroke switch, press to start and press again to stop, ideal for larger parts. Voltage regulator to keep the voltage as constant as possible. Includes: electrode holder with 1.5m 25mm² cable MLT15M3 MIG torch with euro connector and 2.5m cable welding ground clamp with 2m 16mm² cable 3x welding spit: 0.6 / 0.8 / 0.9mm 2x hose clamps 1x thread drive roll: 0.6 + 0.8mm

Specifications:

-

Frequency

50 Hz

-

Voltage

230V

-

No load voltage

62V

-

Input power

5.7kVA

-

Circuit breaker

16A B-char

-

Duty cycle @20C

60% - 160A

-

Insulation class

H

-

Duty cycle @40C

30% - 160A

-

Welding current range

MIG 30 - 160A / MMA 30 - 140A / TIG 30 - 140A

-

Weldable welding wire

0.6 / 0.8 / 1.0 mm

-

Protection class

IP21S

-

Dimensions

420.0mm x195.0mm x300.0mm

-

Weight

10.0Kg

Strongpoints:

Infinitely adjustable

High-quality aluminum wire feeder

Interchangeable MIG torch with euro connector

IGBT inverter technology

Light, compact, mobile

Downloads:

MG200

MIG welding machine Thanks to the 230/400V switch, the Soldatech Original MG200 can be used everywhere. The transformer welding machine is suitable for both welding with gas as FLUX welding without gas, and is used for welding of steel/aluminum or stainless steel when using the appropriate optional accessories. The machine has a continuous adjustable wire speed with 6 welding positions.

Note: Comes

Every MG200 comes standard including: Adapter 230V to 400V with 30cm cable MLT24M3 MIG torch with euro connector and 3m cable Welding ground clamp with 1.5m 16mm² cable 3x welding spit: 0.6 / 0.8 / 1.0mm 2x hose clamps 1x thread drive roll: 0.6 + 0.8mm without a regulator.

Furthermore, the device is equipped with thermal protection and is cooled by a fan.

Ideal for welding carbon steel, low alloy steel and stainless steel.

Specifications:

-

Frequency

50 Hz

-

Voltage

230V - 400V

-

No load voltage

36V

-

Input power

9,2kW

-

Mig voltage range

18 - 38V

-

Circuit breaker

16A C-char

-

Duty cycle @20C

25% - 200A

-

Insulation class

H

-

Duty cycle @40C

10% - 200A

-

Welding current range

MIG/MAG 50 - 200A

-

Weldable welding wire

0.6 / 0.8 / 1.0 / 1.2 mm

-

Protection class

IP21S

-

Dimensions

850.0mm x420.0mm x590.0mm

-

Weight

50.0Kg

Strongpoints:

Can be used on both 230V and 400V

Interchangeable MIG torch with euro connector

Thermal protection

Platform for gas cylinder including set of wheels and chain for locking the gas cylinder

ML160HG

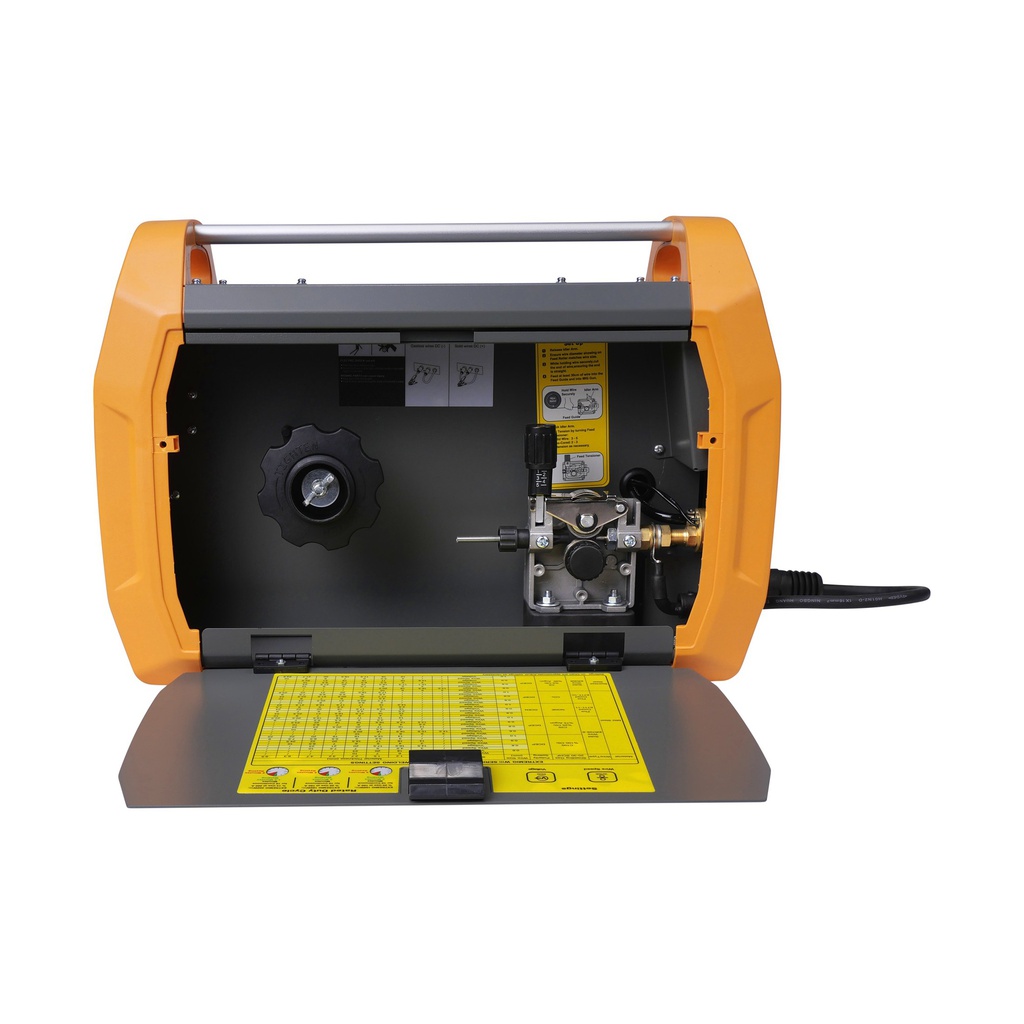

MIG/MAG 160A welding inverter / welding machine This Soldatech powered by HG portable welding machine is a handy and versatile machine with which various welding processes including MIG welding, Lift-TIG and also electrode welding can be performed with ease. The wire speed is automatically adjusted to the set amperage, ensuring professional results. The modern IGBT inverter technology ensures that the ML160HG delivers sustainable performance with more power and a very high duty cycle. The ML160HG is also equipped with thermal safety as standard, which in combination with a built-in fan prevents overheating and ensures that high-quality welding performance is guaranteed for a long time. The hot-start/anti-stick function increases the welding current quickly, so that the electrode does not stick to the workpiece during ARC welding. Ideal for welding stainless steel, carbon steel, low alloy steel and aluminium (MIG). Each ML160HG comes standard including: Soldatech MLT15M3 MIG torch with Euro connector and 3m cable Welding ground clamp with 2m 16mm² cable European Dinse couplers 13mm Gas line including NW5 quick coupler 3m

Specifications:

-

Frequency

50/60 Hz

-

Voltage

230V - 1 Phase

-

Circuit breaker

16A B-kar

-

Input power

6.84kVA

-

No load voltage

68V

-

Weldable welding wire

0.6 / 0.8 / 1.0 mm

-

Protection class

IP21S

-

Duty cycle @40C

20% - 160A

-

Welding current range

MIG 30 - 160A / MMA 30 - 130A / TIG 20 - 160A

-

Duty cycle @20C

40% - 160A

-

Dimensions

490.0mm x200.0mm x335.0mm

-

Weight

11.0Kg

Strongpoints:

High-quality aluminum wire feeder

Lift-TIG function

Infinitely adjustable

ABS shock resistant housing

5 years warranty

Downloads:

ML200HG

MIG/MAG 200A welding inverter / synergetic inverter / welding machine This portable Soldatech powered by HG synergistic welding machine makes it possible to perform different welding processes including MIG welding, Lift-TIG and also electrode welding with ease. The wire speed is automatically adjusted to the set amperage, ensuring professional results. The clear LCD display makes the ML200HG very easy to set up and all welding settings can be easily managed. The applications in the LCD screen and the synergistic properties of the machine make welding with this unit a real pleasure for almost all materials without the need for complicated settings. With this machine it is possible to braze with CuSi3, the copper-silicon alloy has a lower melting temperature than steel, so that less temperature enters the material to be soldered and there is less chance of deformation of (thin) plates. It is also possible to solder different materials together (eg. aluminum to steel). The welding torch is also equipped with the latest torch-control technology, making it very easy to adjust the welding machine remotely and even while welding. The modern IGBT inverter technology ensures that the ML200HG delivers sustainable performance with more power and a very high duty cycle. The ML200HG is also equipped with thermal safety as standard, which in combination with a built-in fan prevents overheating and ensures that high-quality welding performance is guaranteed for a long time. The Soldatech inverter has a very extensive database that makes it possible to save 5 different programs with welding settings. This makes it easy to manage the ideal settings. The hot-start/anti-stick function increases the welding current quickly, so that the electrode does not stick to the workpiece during ARC welding. Ideal for welding stainless steel, carbon steel, low alloy steel, copper and aluminum (MIG). Each ML200HG comes standard including: Soldatech MLT25M3R remote control MIG torch with Euro connector and 3m cable Twistlock electrode torch with 3m 16mm² cable Welding ground clamp with 2m 16mm² cable European dinse couplers 13mm Gas line including quick coupling 3m

Specifications:

-

Frequency

50/60 Hz

-

Voltage

230V - 1 Phase

-

No load voltage

69V

-

Input power

8.6kVA

-

Circuit breaker

16A C-char

-

Protection class

IP21S

-

Duty cycle @40C

20% - 200A

-

Duty cycle @20C

35% - 200A

-

Weldable welding wire

0.6 / 0.8 / 1.0 / 1.2 mm

-

Welding current range

MIG 40 - 200A / MMA 10 - 180A / TIG 10 - 180A

-

Dimensions

550.0mm x245.0mm x405.0mm

-

Weight

19.0Kg

Strongpoints:

LCD-display for welding settings

Remote control MIG torch

High-quality aluminum wire feeder

Synergetic

5 years warranty

Downloads:

ML200YHG

MIG/MAG 200A welding inverter / inverter / welding machine This Soldatech powered by HG MIG / MAG welding machine is standard equipped with a carrying platform to attach the gas bottle. This machine makes it possible to carry out various welding processes with ease, including MIG welding and also electrode welding. The modern IGBT inverter technology ensures that the ML200YHG delivers sustainable performance with more power and a very high duty cycle. The ML200YHG is also equipped with thermal safety as standard, which in combination with a built-in fan prevents overheating and ensures that high-quality welding performance is guaranteed for a long time. The hot-start/anti-stick function increases the welding current quickly, so that the electrode does not stick to the workpiece during ARC welding. Ideal for welding stainless steel, carbon steel, low alloy steel and aluminium (without pulse). Each ML200YHG comes standard with: Soldatech MLT24M3 MIG torch with Euro connector and 3m cable Welding ground clamp with 3m 25mm² cable European 13mm Dinse couplers Gas line including quick coupling 4m 3-pin 32A plug with 3m 3x4mm² cable 1x wire feed roll: 0.8 + 1.0

Specifications:

-

Frequency

50/60 Hz

-

Voltage

230V - 1 Phase

-

No load voltage

76V

-

Input power

10kVA

-

Circuit breaker

16A C-char

-

Duty cycle @20C

100% - 200A

-

Duty cycle @40C

60% - 200A

-

Welding current range

MIG 30 - 200A / MMA 20 - 200A

-

Weldable welding wire

0.8 / 1.0 / 1.2 mm

-

Protection class

IP21S

-

Dimensions

990.0mm x495.0mm x720.0mm

-

Weight

44.5Kg

Strongpoints:

Tray with wheels and chain for gas bottle

Double wire feed

Infinitely adjustable

ABS shock resistant housing

5 years warranty

Downloads:

ML250YHG

MIG/MAG 250A welding inverter / inverter / welding machine This Soldatech powered by HG MIG / MAG welding machine is standard equipped with a carrying platform to attach the gas bottle. This machine makes it possible to carry out various welding processes with ease, including MIG welding and also electrode welding. The modern IGBT inverter technology ensures that the ML250YHG delivers sustainable performance with more power and a very high duty cycle. The ML250YHG is also equipped with thermal safety as standard, which in combination with a built-in fan prevents overheating and ensures high-quality welding performance for a long time. The hot-start/anti-stick function increases the welding current quickly, so that the electrode does not stick to the workpiece during ARC welding. Ideal for welding stainless steel, carbon steel, low alloy steel and aluminium (without pulse). Each ML250YHG comes standard with: MLT24M3 MIG torch with Euro connector 3m cable Welding ground clamp with 3m 25mm² cable European dinse couplers 13mm Gas line including quick coupling 4m

Specifications:

-

Frequency

50/60 Hz

-

Voltage

400V - 3 Phase

-

No load voltage

70V

-

Input power

11kVA

-

Circuit breaker

16A C-char

-

Duty cycle @20C

80% - 250A

-

Duty cycle @40C

60% - 250A

-

Welding current range

MIG 30 - 250A / MMA 20 - 200A

-

Weldable welding wire

0.8 / 1.0 / 1.2 / 1.6 mm

-

Protection class

IP21S

-

Dimensions

900.0mm x450.0mm x710.0mm

-

Weight

47.0Kg

Strongpoints:

Tray with wheels and chain for gas bottle

Double wire feed

Infinitely adjustable

ABS shock resistant housing

5 years warranty

Downloads:

ML350YHG

MIG/MAG 350A welding inverter / synergetic inverter / welding machine This Soldatech powered by HG MIG / MAG welding machine is standard equipped with a carrying platform to attach the gas bottle. This machine makes it possible to carry out various welding processes with ease, including MIG welding and also electrode welding. The modern IGBT inverter technology ensures that the ML350YHG delivers sustainable performance with more power and a very high duty cycle. The ML350YHG is also equipped with thermal safety as standard, which in combination with a built-in fan prevents overheating and ensures that high-quality welding performance is guaranteed for a long time. Furthermore, the mobile wire feed unit is equipped with a control panel on which welding voltage and current strength, among other things, can be easily adjusted. The power source is also equipped with preprogrammed synergetic programs for welding various materials. The hot-start/anti-stick function increases the welding current quickly, so that the electrode does not stick to the workpiece during ARC welding. Ideal for welding stainless steel, carbon steel, low alloy steel and aluminium (without pulse). Each ML350YHG comes standard including: Soldatech MLT36M4 MIG torch with Euro connector and 4m cable Welding ground clamp with 3m 35mm² cable European dinse couplers 13mm Gas line including quick coupling 7m Intermediate cable bundle grommet 5m 5-pin 32A plug with 3.5m 4x4mm² cable 4x Wire drive roll: 2x 0.8 + 1.0 and 2x 1.2 + 1.6

Specifications:

-

Frequency

50/60 Hz

-

Voltage

400V - 3 Phase

-

No load voltage

73V

-

Input power

16.8kVA

-

Circuit breaker

32A B-char

-

Duty cycle @20C

100% - 350A

-

Duty cycle @40C

60% - 350A

-

Welding current range

MIG 40 - 350A / MMA 40 - 350A

-

Weldable welding wire

0.8 / 1.0 / 1.2 / 1.6 mm

-

Protection class

IP21S

-

Dimensions

1000.0mm x420.0mm x1200.0mm

-

Weight

69.0Kg

Strongpoints:

Tray with wheels and chain for gas bottle

Mobile wire feed unit

Synergetic

ABS shock resistant housing

5 years warranty

Downloads:

ML500YHG

MIG/MAG 500A welding inverter / synergetic inverter / welding machine This Soldatech powered by HG MIG / MAG welding machine can be set both synergistically and manually, equipped as standard with a solid trolley that can easily hold a 50L bottle. This synergetic machine makes it possible to perform various welding processes including MIG welding and also electrode welding with ease. The modern IGBT inverter technology ensures that the ML500YHG delivers sustainable performance with more power and a very high duty cycle. The ML500YHG is also standard equipped with a powerful water cooler that, in combination with a built-in fan, prevents overheating and ensures high-quality welding performance is guaranteed for a long time. The mobile wire feeder unit is also equipped with a control panel on which the welding voltage and current, among other things, can be easily adjusted. The power source is also equipped with preprogrammed synergetic programs for welding various materials. Ideal for welding stainless steel, carbon steel, low alloy steel and aluminium (without pulse). Each ML500YHG comes standard with: Water-cooled Soldatech MLT501M4 MIG torch Welding ground clamp with 3m 50mm² cable European dinse couplers 13mm Gas line including quick coupling 12m Intermediate connection bundle 5m 5-pin 32A plug with 3m 4x4mm² cable 4x wire feed roll: 2x 0.8 + 1.0 and 2x 1.2V + 1.6V

Specifications:

-

Frequency

50/60 Hz

-

Voltage

400V - 3 Phase

-

No load voltage

73V

-

Input power

27.5kVA

-

Circuit breaker

32A B-char

-

Cooling unit content

6L

-

Duty cycle @20C

100% - 500A

-

Duty cycle @40C

60% - 500A

-

Welding current range

MIG 40 - 500A / MMA 40 - 490A

-

Weldable welding wire

0.8 / 1.0 / 1.2 / 1.6 mm

-

Protection class

IP21S

-

Dimensions

1133.0mm x498.0mm x1508.0mm

-

Weight

112.0Kg

Strongpoints:

Very high duty cycle

Mobile wire feed unit

Synergetic

ABS shock resistant housing

5 years warranty

Downloads:

ML500YHGM

Pulse MIG/MAG 500A synergetic inverter / welding machine The Soldatech powered by HG MIG Double Pulse is one of the most versatile MIG devices on the market, equipped as standard with a solid trolley that can easily hold a 50L bottle. This synergetic machine makes it possible to easily perform various welding processes including Pulse, Double Pulse, MIG welding and also electrode welding. The modern IGBT inverter technology ensures that the ML500YHGM delivers sustainable performance with more power and a high duty cycle. In addition, the ML500YHGM is equipped as standard with a powerful water cooler which prevents overheating in combination with a built-in fan and ensures that high-quality welding performance is guaranteed over a long period of time. The Soldatech pulse invertor has a very extensive database that allows for 500 different programs with welding settings to be stored. This makes it easy to manage the ideal settings. The mobile wire feeder unit is also equipped with a digital control panel on which the gas after-current settings, welding voltage and current, among other things, can be easily adjusted and read. The power source is also equipped with preprogrammed synergetic programs for aluminum, steel, stainless steel, CuMn, CuSiMn and CuZn materials. Ideal for welding aluminum, stainless steel, carbon steel, low alloy steel and other alloys. Each ML500YHGM comes standard with: Welding ground clamp with 3m 50mm² cable European dinse couplers 13mm Gas line including quick coupling 12m Intermediate cable bundle grommet 10m 5-pin 32A plug with 3m 4x4mm² cable Spare steel inner liner 10x wire feed rollers: (0.8 + 1.0 and 1.2 + 1.6)(0.8 + 1.0U and 0.8 + 1.0V and 1.2V + 1.6V)

Specifications:

-

Frequency

50/60 Hz

-

Voltage

400V - 3 Phase

-

No load voltage

80V

-

Input power

27.5kVA

-

Circuit breaker

32A B-char

-

Cooling unit content

6L

-

Duty cycle @20C

60% - 500A

-

Duty cycle @40C

40% - 500A

-

Welding current range

MIG 30 - 500A / MMA 10 - 500A

-

Weldable welding wire

0.8 / 1.0 / 1.2 / 1.6 mm

-

Protection class

IP21S

-

Dimensions

1133.0mm x498.0mm x1508.0mm

-

Weight

120.0Kg

Strongpoints:

Pulse, double Pulse

Cable package of 10m

Mobile wire feed unit

ABS shock resistant housing

5 years warranty

Downloads: